-

UASB Anaerobic Tower Anaerobic Reactor

The gas, solid and liquid three-phase separator is set at the upper part of the UASB reactor. The lower part is the sludge suspension layer area and the sludge bed area. The waste water is evenly pumped into the sludge bed area by the bottom of the reactor and fully contacts with the anaerobic sludge, and the organic matter is decomposed into biogas by anaerobic microorganisms.The liquid, gas and solid form a mixed liquid flow rises to the three-phase separator, making the three well separated, making more than 80% of the organic matter transformed into biogas, and completing the wastewater treatment process.

-

High cod organic wastewater treatment anaerobic reactor

The structure of IC reactor is characterized by a large height diameter ratio, generally up to 4 -, 8, and the height of the reactor reaches 20 left m right. The whole reactor is composed of a first anaerobic reaction chamber and a second anaerobic reaction chamber. A gas, solid and liquid three-phase separator is set at the top of each anaerobic reaction chamber. The first stage three-phase separator mainly separates biogas and water, the second stage three-phase separator mainly separates sludge and water, and the influent and reflux sludge are mixed in the first anaerobic reaction chamber. The first reaction chamber has great ability to remove organic matter. The wastewater entering the second anaerobic reaction chamber can continue to be treated to remove the remaining organic matter in the wastewater and improve the effluent quality.

-

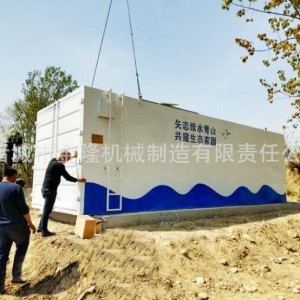

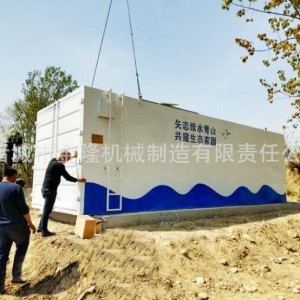

Package type sewage waste water treatment System

The level 2 biological contact oxidation process adopts the patent aerator, it doesn’t require complicated pipe fittings. Compared with the activated sludge tank, it has a smaller size and a better adaptability to water quality and stable outlet water quality. No sludge expansion.

-

Carbon Steel Fenton Reactor For Wastewater Treatment

Fenton reactor, also known as Fenton fluidized bed reactor and Fenton reaction tower, is a necessary equipment for advanced oxidation of wastewater by Fenton reaction. Based on the traditional Fenton reaction tower, our company has developed a patented Fenton fluidized bed reactor. This equipment uses the fluidized bed method to make most of the Fe3 + produced by Fenton Method attached to the surface of the fluidized bed Fenton carrier by crystallization or precipitation, which can greatly reduce the dosage of traditional Fenton Method and the amount of chemical sludge produced (the addition of H2O2 is reduced by 10% ~ 20%).

-

Wsz-Ao Underground Integrated Sewage Treatment Equipment

1. Equipment can be fully buried, semi-buried or placed above the surface, not arranged in standard form and set according to the terrain.

2. The buried area of equipment basically does not cover the surface area, and can not be built on green buildings, parking plants and insulation facilities.

3. Micro-hole aeration uses the aeration pipeline produced by German Otter System Engineering Co., Ltd. to charge oxygen, not blocking, high oxygen charging efficiency, good aeration effect, energy saving and power saving.

-

Wsz-Mbr Underground Integrated Sewage Treatment Equipment

The device has assembly function: integrating oxygen deficiency tank, MBR bioreaction tank, sludge tank, cleaning tank and equipment operation room in a large box, compact structure, simple process, small land area (only 1 / -312 / of the traditional process), convenient incremental expansion, high automation, and anytime and anywhere, the device can be directly transported to the treatment target location, direct scale, without secondary construction.

Gathering sewage treatment and water treatment process in the same device, can be buried underground or surface; basically no sludge, no impact on the surrounding environment; good operation effect, high reliability, stable water quality and less operation cost.