Characteristics

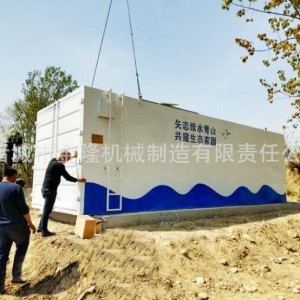

1. Equipment can be fully buried, semi-buried or placed above the surface, not arranged in standard form and set according to the terrain.

2. The buried area of equipment basically does not cover the surface area, and can not be built on green buildings, parking plants and insulation facilities.

3. Micro-hole aeration uses the aeration pipeline produced by German Otter System Engineering Co., Ltd. to charge oxygen, not blocking, high oxygen charging efficiency, good aeration effect, energy saving and power saving.

4. Adopts integrated design, less land occupation, low investment province and low operating cost.Equipped with a fully automatic control system.

5. Has new process, good effect, less sludge; convenient operation and maintenance; small noise, long service life, and can operate continuously for more than 10 years.

Application

It is applicable to the treatment of various industrial organic sewage from hotels, hotels, nursing homes, hospitals, schools, shopping malls, shopping malls, residential areas, ship docks, ships, stations, airports, factories, mines, tourist spots, scenic spots and other domestic sewage.

Technique Parameter

Note: 1. When water inlet BOD5 ≤ 200mg/L, water outlet BOD5 ≤ 30mg/L.

The height of 2, inspection hole is 300; H: equipment height; H1: inlet water pipe from the ground; H2: outlet pipe from the ground; nominal diameter of DN1: inlet pipe;

N 2: outlet pipe nominal straight D diameter.