-

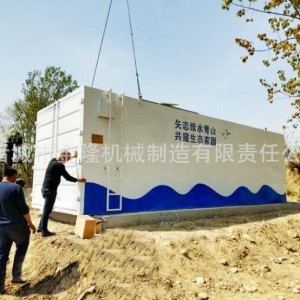

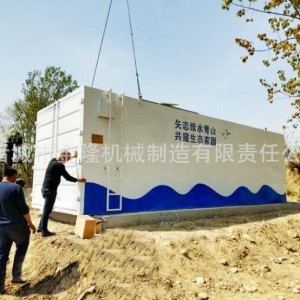

Containerized sewage treatment plant for sewage treatment

The integrated sewage treatment equipment adopts advanced biological treatment technology. Based on the operating experience of domestic sewage treatment equipment, an integrated organic wastewater treatment device is designed, which integrates the removal of BOD5, COD, and NH3-N. It has stable and reliable technical performance, good treatment effect, low investment, automated operation, and convenient maintenance and operation

-

Portable Package Integrated sewage treatment equipment/ domestic sewage treatment system

Integrated sewage treatment equipment is a comprehensive sewage treatment system that integrates multiple treatment methods such as biology, chemistry, and physics. Efficient purification of wastewater is achieved through multiple processes such as pretreatment, biological treatment, and post-treatment. This type of equipment has the advantages of small footprint, high treatment efficiency, energy conservation and environmental protection, and is widely used in the treatment of domestic sewage and some industrial wastewater in residential communities, schools, hospitals, hotels, restaurants, and other areas.

-

Package type sewage waste water treatment System

The level 2 biological contact oxidation process adopts the patent aerator, it doesn’t require complicated pipe fittings. Compared with the activated sludge tank, it has a smaller size and a better adaptability to water quality and stable outlet water quality. No sludge expansion.

-

Wsz-Ao Underground Integrated Sewage Treatment Equipment

1. Equipment can be fully buried, semi-buried or placed above the surface, not arranged in standard form and set according to the terrain.

2. The buried area of equipment basically does not cover the surface area, and can not be built on green buildings, parking plants and insulation facilities.

3. Micro-hole aeration uses the aeration pipeline produced by German Otter System Engineering Co., Ltd. to charge oxygen, not blocking, high oxygen charging efficiency, good aeration effect, energy saving and power saving.

-

Wsz-Mbr Underground Integrated Sewage Treatment Equipment

The device has assembly function: integrating oxygen deficiency tank, MBR bioreaction tank, sludge tank, cleaning tank and equipment operation room in a large box, compact structure, simple process, small land area (only 1 / -312 / of the traditional process), convenient incremental expansion, high automation, and anytime and anywhere, the device can be directly transported to the treatment target location, direct scale, without secondary construction.

Gathering sewage treatment and water treatment process in the same device, can be buried underground or surface; basically no sludge, no impact on the surrounding environment; good operation effect, high reliability, stable water quality and less operation cost.