-

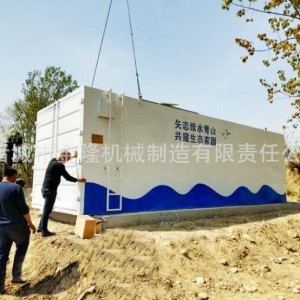

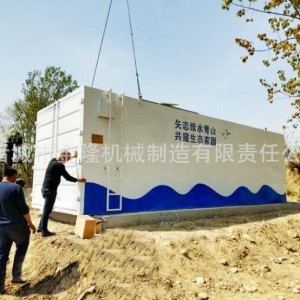

Containerized sewage treatment plant for sewage treatment

The integrated sewage treatment equipment adopts advanced biological treatment technology. Based on the operating experience of domestic sewage treatment equipment, an integrated organic wastewater treatment device is designed, which integrates the removal of BOD5, COD, and NH3-N. It has stable and reliable technical performance, good treatment effect, low investment, automated operation, and convenient maintenance and operation

-

Fully-Automatic Waste Water Treatment Plant Sludge Dewatering Screw Filter Press Mobile Sludge Dewatering System

Mobile portable wastewater treatment plant is a movable vehicle type sludge dewatering complete system which is easy to move.It can be of service for different sewage treatment sites in different places.The unit is mainly composed of screw type dehydrator, integrated polymer preparation unit, polymer feed pump, sludge pump and sludge conveyor. -

Micro Rotary Drum Filter for Wastewater Filtration

Micro filtration machine, also known as rotary drum grille, is a purification device that uses 80-200 mesh/square inch microporous screen fixed on the rotary drum filtration equipment to intercept solid particles in wastewater and achieve solid-liquid separation.

-

Portable Package Integrated sewage treatment equipment/ domestic sewage treatment system

Integrated sewage treatment equipment is a comprehensive sewage treatment system that integrates multiple treatment methods such as biology, chemistry, and physics. Efficient purification of wastewater is achieved through multiple processes such as pretreatment, biological treatment, and post-treatment. This type of equipment has the advantages of small footprint, high treatment efficiency, energy conservation and environmental protection, and is widely used in the treatment of domestic sewage and some industrial wastewater in residential communities, schools, hospitals, hotels, restaurants, and other areas.

-

Cheap PriceList for Screw Stacked Type Biogas Manure Slurry Sludge Dewatering Machine Solid Liquid Separator

ZDL Sludge dewatering machine set automatic control cabinet ,flocculation conditioning tank ,sludge thickening and dewatering body and a collecting tank and integration ,can be in automatic operation conditions, to achiece efficient flocculation ,and continuously complete sludge thickening and dewatering work ,will eventually collected filtrate recirculation or discharge.

-

2850 SLANTING SPRAY FORMING HIGH SPEED PAPER MACHINE

Quantitative range: 13-40g/m

Net paper width: 3000mm

Working speed: 400-550m/min

Design speed: 600m/min

Crawling speed: 25m/min

Dynamic balance speed: 650m/min

Transmission mode: segment transmission, AC variable frequency control

Gauge: 4100mm

Arrangement form: a layer of arrangement, divided into left and right mobile phone Nominal output: 20-25t/d -

Toilet paper making machinery

Paper machine is a collective term for a complete set of equipment that forms a paper web for pulp, including a main unit such as a pulp box, a mesh unit, a pressing unit, a drying unit, a calendering machine, a paper rolling machine, and a transmission unit, as well as auxiliary systems such as steam, water, vacuum, lubrication, and heat recovery.

Our company can provide customers with a complete set of paper production lines, including pulp systems, toilet paper machines, and sewage treatment equipment.

its main characteristics are low sizing consistency ,large pressure ,eveccess,quick moulding and good evenness,wide quantitation scope (13g~38g/㎡),high vehicle speed (150~200m/min),large output ,low energy consumption,main models:1092,1575,1760,1880,2362,2800,3600mm.

-

Package type sewage waste water treatment System

The level 2 biological contact oxidation process adopts the patent aerator, it doesn’t require complicated pipe fittings. Compared with the activated sludge tank, it has a smaller size and a better adaptability to water quality and stable outlet water quality. No sludge expansion.

-

Sewage treatment decanting device, rotary decanter

Application Bsx rotary decanter is a special mechanical equipment for sewage treatment with ... -

Belt Type Filter Press

Sludge Dewatering Belt Filter Press Machine is a kind of dewatering machine developed on the basis of advanced foreign technology. It features large treating capacity, high dewatering capacity and long life time. As a part in waste water treatment system, it is used for dewatering of suspended particles and residue after treated so as to avoid secondary pollution. It is also applicable for treatment of thickner concentration and black liquor extraction.

-

Wsz-Ao Underground Integrated Sewage Treatment Equipment

1. Equipment can be fully buried, semi-buried or placed above the surface, not arranged in standard form and set according to the terrain.

2. The buried area of equipment basically does not cover the surface area, and can not be built on green buildings, parking plants and insulation facilities.

3. Micro-hole aeration uses the aeration pipeline produced by German Otter System Engineering Co., Ltd. to charge oxygen, not blocking, high oxygen charging efficiency, good aeration effect, energy saving and power saving.

-

ZDL stacked spiral sludge dewatering machine

ZDL Sludge dewatering machine set automatic control cabinet ,flocculation conditioning tank ,sludge thickening and dewatering body and a collecting tank and integration ,can be in automatic operation conditions, to achiece efficient flocculation ,and continuously complete sludge thickening and dewatering work ,will eventually collected filtrate recirculation or discharge.